Lithium-ion Batteries

Lithium-ion batteries use a myriad of advanced materials, each of which must have specific properties to enable the operation of the battery, so that it can power modern electric vehicles, power tools, laptops and electronic gadgets.

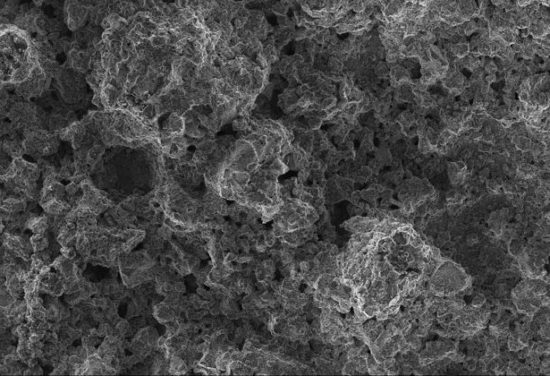

Many materials used to produce today’s lithium-ion batteries are applied in the form of pastes, slurries and coatings. Once processed, these materials form a cell component (cathode, anode, coating) which must meet specific requirements for ionic conductivity, electronic properties, film morphology, stability upon cycling, and many more. Therefore, formulation expertise is a key to designing and producing a top performing battery cell.

Our materials and expertise have been used in several areas of lithium-ion battery technology.

- Anode coatings based on graphene and graphite.

- Graphene conductive coatings on copper and aluminium foils for improved adhesion, interfacial properties and improved conductivity of anode and cathode coatings.

- MoS2 and WS2 composite anode formulations for lithium-ion and sodium-ion batteries.

- Activated carbon paste for electro-chemical cells.

Anode coating for lithium-ion batteries developed by our company

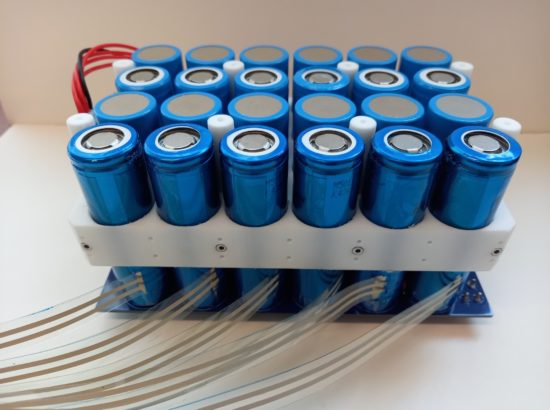

Our advanced materials also find use in the assembly and diagnostics of lithium-ion battery packs, which can contain just a few cells (for example, in power tools), or thousands of cells (as in electric vehicles). We offer unique innovative solutions which make battery packs safer, enable monitoring and predictability of individual cells, and help testing and prototyping of new battery pack concepts, including structural batteries.

Our battery pack technical solutions include:

- Battery cell joining technology utilising our specialist conductive adhesives, eliminating the need for expensive laser welding equipment. This novel method of joining cells allows the production and testing of novel pack designs and prototypes without specialist and costly tooling.

- Printed sensors for monitoring and predicting the state-of-health and safety of individual lithium-ion cells of different formats, whether cylindrical, pouch, or prismatic. The technology can also be applied as a battery diagnostics tool during the development of novel cell chemistries and designs, for example to assess cell swelling and overheating.

Please contact us to learn more about lithium-ion battery expertise and technical solutions.

Lithium-ion cells of 2170 format fitted with printed sensors and assembled into a battery pack enabling the monitoring and diagnostics of individual cells